Power line Inspection

Nowadays, smart grid has got rapid development due to the emergence of many new technologies. The construction of smart grid has entered a comprehensive and fast growth stage. A large number of new power lines have been put into real operation. It correspondingly causes that transmission line mileage and power equipment’s have got grown rapidly. Therefore, to ensure an uninterrupted running of the power system, the monitoring, detection, and maintenance of power transmission system are faced with huge challenges, and they also play the important roles in addressing the issue of smart grid.

With the fast development of smart grid, the power line mileage and power equipment’s get rapid growth.

The contradiction between the large number of maintenance equipment’s and the small number of maintenance workers becomes increasingly prominent. Meanwhile, the traditional maintenance mode has the disadvantages of over or under maintenance, which will lead to the increasing failure risk of power transmission system. Faced with these issues, to enhance the intelligence and automation level of power line inspection, many researchers have devoted much effort to the research of automatic power line inspection and some state-of-the-art techniques about power line inspection are proposed to improve the inspection efficiency and quality, such as unmanned aerial vehicle (UAV), image processing, deep architecture, and so on. In this article, we analyzed and summarized the state-of-the-art techniques on power line inspection to provide a valuable reference for the researchers engaged in the smart grid

The purpose of this proposal is to outline the operation of data capture Powerline Inspection – Insulators and obstructions – foliage and other potential outage risks.

Thermal Inspection

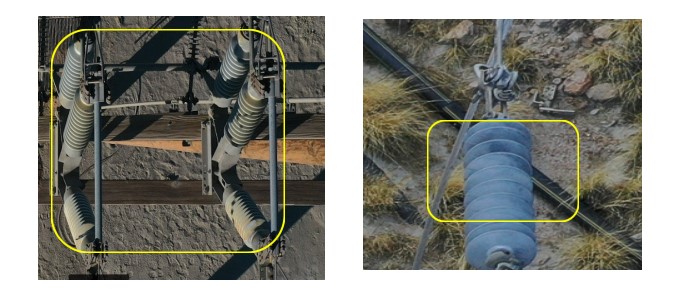

Infra-red inspection- Infrared photography is a widely used technique both for initial inspection of a power line and closer up inspection to confirm a suspected faulty connection. Infrared photography allows visual inspection of the heat being dissipated by the power line using microbolometer arrays which are designed to detect a certain range of infrared wavelengths. The most well-known manufacturer of infrared cameras is FLIR systems. Their cameras are widely used in helicopter inspection of power lines. Using infrared photography, utilities can observe areas of high resistivity, corrosion, faulty splices, insulator leakage currents, and bad connections which cause heat.

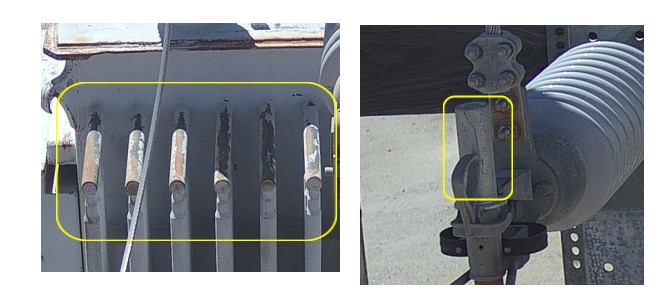

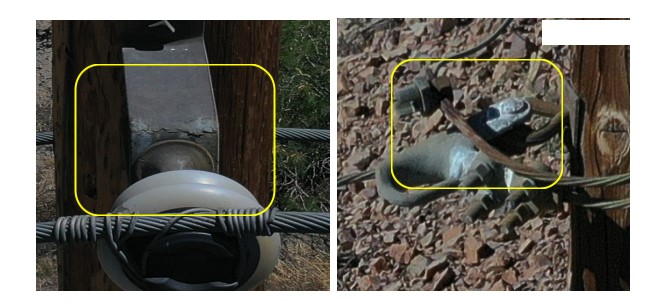

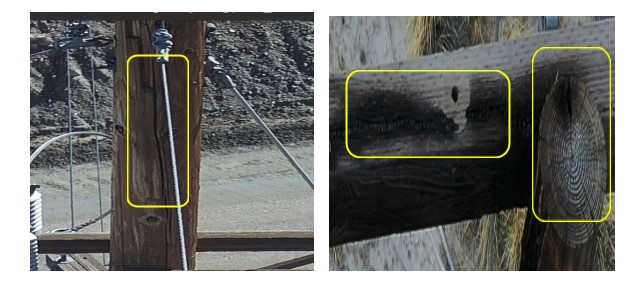

Visual Inspection- Visual inspection of the lines is important. Many problems are found by linemen or other power company workers simply noticing something wrong while going from place to place. It is good to keep an eye out for any fraying in the line abrasion, or other damaging of connections or components so they can be replaced or analyzed further. Unmanned aerial systems (UAS) can be used nowadays for automatic visual inspection of power lines. Two challenging problems need to be solved: The detection of the power lines and the tracking of the lines

Visual Inspection